LJSH ---Three cylinder dry mortar dryer machine

Basisinformation

Modell: HJ-Series

Produktbeschreibung

Specifications

three cylinder drying equipment,LJSH1.Capacity according to the LJSH inter diameter

2.Moisture based on the cylinder length

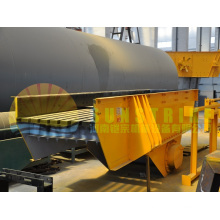

LJSH ---Three cylinder dry mortar dryer machine

Summary ofthree cylinder drying equipment,LJSH

The characteristics of sand drying technology are low-moisture material, good fluidity, large production and small granule. The moisture and granularity of granule material must be in the required range during the drying process. Commonly, it applies to the yellow sand used in dry mortar industry and sand of various specification used in casting industry. Different industries have different requirements for the moisture of the dried material. At last, the moisture of material can reach under 0.5-1%. Therefore, it can meet the requirement for moisture of every industry.

Application of three cylinder drying equipment,LJSH

Sand dryer is also known as three-return sand dryer. It mainly applies to bulk materials like sand, river sand, yellow sand, silica sand, pomegranate sand, copper sludge, slag, perlite and materials used in casting industry like sand, blast furnace slag, granular clay of various specifications.

Technology process of three cylinder drying equipment,LJSH

The sand dryer is made up of feeder, belt conveyor, three-return sand dryer, hot-blast stove, linear vibrating screen, lifter and dedusting system. During sand drying process, the sand is first sent to belt conveyor by the feeder, then through quicksand tube to the inside of the dryer. Heat produced by the burning of materials in the hot-blast stove enters into the inside of the main machine with the working of exhaust fan to touch the sand, thus heat deliver is finished. The dried sand flows to the belt conveyor from the hopper, then after being screened by linear vibrating screen to the storage place. At last, the sand is packaged with the help of lifter. The dust in the sand is discharged up the hopper. Then it will be dealt with by the dedusting system. So it's very environmental.

Technical parameters of three cylinder drying equipment,LJSH

Model Specification |

φ2*4.5m |

φ2.2*5m |

φ2.5*6m |

φ2.7*6.5m |

φ3.0*6.5m |

φ3.2*7m |

φ3.6*8m |

φ4.2*8m |

Diameter of Outer Cylinder(m) |

2 |

2.2 |

2.5 |

2.7 |

3.0 |

3.2 |

3.6 |

4.2 |

Length of Outer Cylinder(m) |

4.5 |

5 |

6 |

6.5 |

6.5 |

7 |

8 |

8 |

Cylinder Volume(m3) |

14.13 |

18.99 |

29.43 |

37.19 |

45.92 |

56.27 |

81.39 |

110.78 |

Revolving Rate(r/min) |

4~10 |

|||||||

Temperature of Inlet Air (C°) |

180 C°~800C° |

|||||||

Yield Production(Ton/Day) |

13~18 |

15~23 |

20~28 |

24~33 |

35~40 |

40~60 |

55~75 |

70~120 |

Engine Power(KW) |

5.5*2 |

7.5*2 |

5.5*4 |

7.5*4 |

11*4 |

15*4 |

18.5*4 |

22*4 |

Remarks |

Besides the above models, we can also supply special models as your request. |

|||||||

More pictures of three cylinder drying equipment,LJSH

Delivery and packing for three cylinder drying equipment,LJSH

Certification of Hengjia Machinery

About Zhengzhou Hengjia Machinery

Zhengzhou Hengjia Machinery Manufacturing Co. , Ltd. is a joint-equity enterprise, which is specialized in research and development, producing and manufacturing of all kinds of drying machinery and energy conservation and environmental protection heat source.

The dryer developed by our corporation for the drying of coal slime, sludge, saw dust, sand, coal ash, flue gas desulfurization gypsum, sprayed corn bran and all kinds of food and mining industry has professional technical ability and distinguished product performance and sell very well in more than 30 provinces of China, also in abroad, like Russia, Korea, Vietnam, India, Malaysia, Indonesia, Pakistan and so on.

Why Choose Us

1. We are Factory (Not Dealer)

All machineries from Zhengzhou Hengjia Machinery Manufactory are made by ourselves, with lower price, good quality and assured full after service. So please buy machine from our factory.

2. Training & Service

♥ Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design and manufacture equipment according to your special demand.

♥ Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

♥ After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

♥ In addition, we provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

3. If you are new for this business, we will help you

Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments.

4. We’d like to recommend a suitable type for you and send you a best quotation. Some questions please inform us in your enquiry.

♥ What is material you want to be dried?

♥ What is the original moisture before drying and your request moisture after drying?

♥ How big handling capacity or output you need?

Looking forward to your kind inquiry and welcome to our factory!

Produktgruppe : Umweltschutz-Ausrüstung

Premium Related Products