Hengjia high efficiency biomass gasifier cheap on sale

Basisinformation

Modell: According to technical data

Produktbeschreibung

Hengjia high efficiency biomass gasifier cheap on sale

Advantages of biomass gasifier:

1. Technical advantage: Adopt draft-down fixed bed type, lower temperature anaerobic pyrolysis, syngas includes lower tar, gas output stable, adopt the PLC control system, one worker on duty, safety and stable.

2. Energy-saving advantage: Energy can save 60%-80% comparing with natural gas and LPG.

3. Environmental advantage: Trace of SO2, CO2 emission, lower than national environmental standard, ash emission is down to 1-1.5%, fuel gas emission under 50 mg/m3.

4. ROI: Fuel coal boiler can recovery cost within 3-4 months, fuel oil (natural gas) boiler can recovery cost within 1-2 months.

5. Application range: Apply to any energy needed enterprise

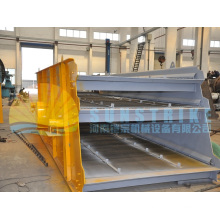

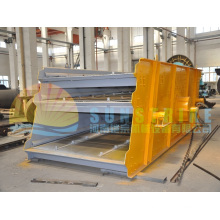

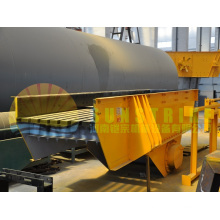

Biomass gasifier structure:

More to know Hengjia biomass gasifier

---Usage

Nowadays, the most commercially successful way is to use biomass gasification for internal combustion engine. This is being widely disseminated and used, because it involves small capacity engines and features flexible in layout, small in investment, integrated in structure, reliable in technology, low in operation cost, outstanding in economic benefit, easy to maintain and operate, and is less demanding on the quality of combustible gas.

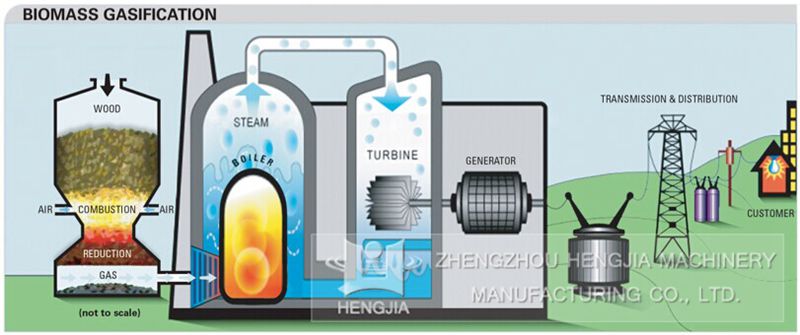

---Our biomass gasification process includes three steps.

*The First step is biomass gasification, which convert biomass into syngas.

**The Second step is syngas purification. The producer gas coming from gasifier usually contains contaminants including dust, coke, tar and etc. The contaminants will be removed by the purification system to ensure normal operation of gas engine.

***The Third step is power generating in gas engine. The high temperature exhaust gas may be reused by waste heat boiler to generate steam or hot water for civil or industrial use. Steam turbine may also be considered to make a gas-steam combined cycle power plant, which will increase the total efficiency.

Technical parameters:

Item |

Model |

HMBG-180 |

HMBG-360 |

HMBG-540 |

HMBG-720 |

HMBG-1200 |

HMBG-1500 |

|

Fuel |

Fuel consumption(kg/h) |

60-120 |

120-240 |

180-360 |

240-480 |

400-800 |

500-1000 |

|

Fuel required |

2cm-8cm wheat straw, rice husk, wood chips, corn cob, cotton straw, peanut shell, etc. |

|||||||

Water content |

10%-15% |

|||||||

Gasification |

Capacity (m3/h) |

150-180 |

300-360 |

500-540 |

600-720 |

1000-1200 |

1300-1500 |

|

Composition of gas |

CO:20-25% H2:8-15% CH4:2-4% CO2:2-4% N2:40-45% O2:≤1.0% |

|||||||

Rate of gasification(Nm3/kg) |

Woody plants: 2-3m3 Herb plants: 1-1.5m3 |

|||||||

Electricity consumption |

kw |

20 |

30 |

37 |

40 |

55 |

60 |

|

Generator |

Capacity (kw) |

50 |

100 |

150-200 |

250-300 |

400-500 |

600-700 |

|

Remarks |

Besides the above general models, we can also supply special model as your request. |

|||||||

About Zhengzhou Hengjia Machinery

Zhengzhou Hengjia Machinery Manufacturing Co. , Ltd. is a joint-equity enterprise, which is specialized in research and development, producing and manufacturing of all kinds of drying machinery and energy conservation and environmental protection heat source.

The dryer developed by our corporation for the drying of coal slime, sludge, saw dust, sand, coal ash, flue gas desulfurization gypsum, sprayed corn bran and all kinds of food and mining industry has professional technical ability and distinguished product performance and sell very well in more than 30 provinces of China, also in abroad, like Russia, Korea, Vietnam, India, Malaysia, Indonesia, Pakistan and so on.

Why Choose Us:

1. We are Factory (Not Dealer)

All machineries from Zhengzhou Hengjia Machinery Manufactory are made by ourselves, with lower price, good quality and assured full after service. So please buy machine from our factory.

2. Training & Service

♥ Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design and manufacture equipment according to your special demand.

♥ Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

♥ After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

♥ In addition, we provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

3. If you are new for this business, we will help you

Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments.

4. We’d like to recommend a suitable type for you and send you a best quotation. Some questions please inform us in your enquiry.

♥ What is the kind of biomass you will use?

We have nearly 10 years experiences, any questions or interesting, please contact us freely.

Skype: lisa.hjm

Welcome to visit our factory in Zhengzhou, China.

Produktgruppe : Vergaser-Ausrüstung > Biomassevergaser